Dimensional Testing and Calibration | Coordinate Measurement (CMM) | 3D Scanning

Dimensional Testing and Calibration

ASF offers Dimensional Testing & Calibration Services from NABL accredited facility to ensure reliable, precise, traceable measurement results from the measuring instruments.

The dimensional testing capabilities includes testing of various geometric dimensions such as length, perpendicularity, circularity, parallelism, contours, profiles and even the surface roughness.

The calibration of instruments such as CMM, Roughness tester, Contour measurement, Vision measurement, gauges, callipers, verniers, micrometers, V-blocks and fixtures etc. is offered to reduce risk and inaccuracy in measurements.

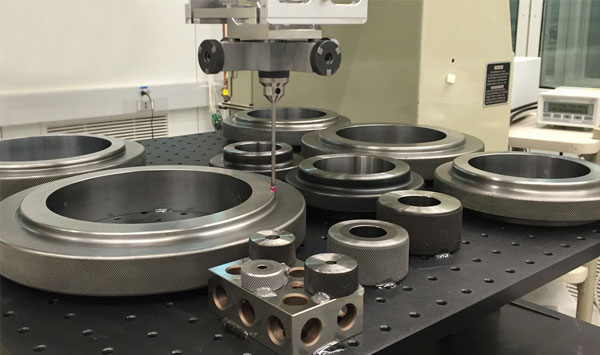

Coordinate Measurement (CMM)

Zeiss make, Coordinate Measuring Machine (CMM) at ASF is installed to precisely measure countless critical components with complex shape and complicated drawing indications. The CMM is capable of measuring any component accurately, up to 5-micron, as can measure multiple components with a CNC program. It can determine conformity to the tolerances provided by technical drawings or CAD models. The final report indicating the results is auto generated by the CMM ensuring its validity and acceptance by various organizations.

3D Scanning

Zeiss make high precision 3 D scanner is available to collect and measure millions of coordinates / data points on the surface of an object with high degree of accuracy to fulfill the need of Reverse engineering of damaged parts, verification of measurements, tolerances and checking of complex geometry.

3-D scanning has revolutionized the way of collecting machinable data required by various industries and is very widely used for prototyping, modelling & re-engineering by generation of digital point cloud data of physical objects.